Baader Fish Processing Line, an all-in-one solution consisting of three specialized machines for fish processing. These machines work together to ensure a continuous flow and optimal results at every stage of the process.

Main Components:

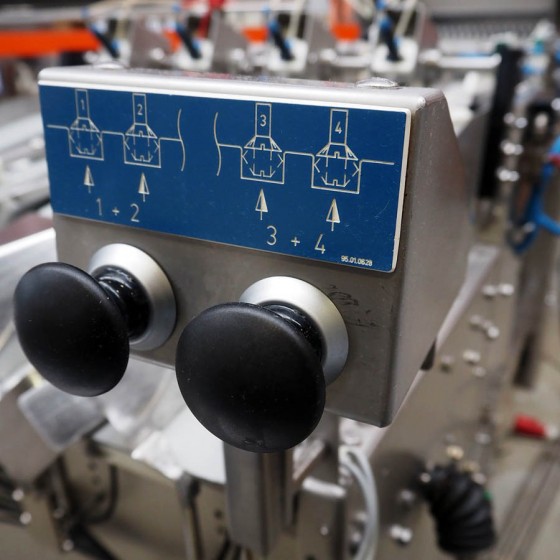

1. Baader 484 4-Lane Automatic Feeder

- Function: Automatically feeds fish into the processing line to ensure a continuous flow.

- Machine Number: 10037/100114

- Year of Manufacture: 1997

- Electrical Specifications: 400 V, 3 Ph, 50 Hz, 21 A

- Dimensions: 3300 mm x 1500 mm x 1850 mm

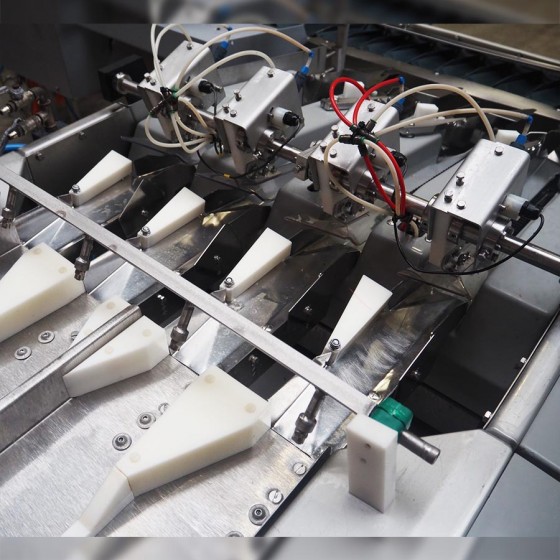

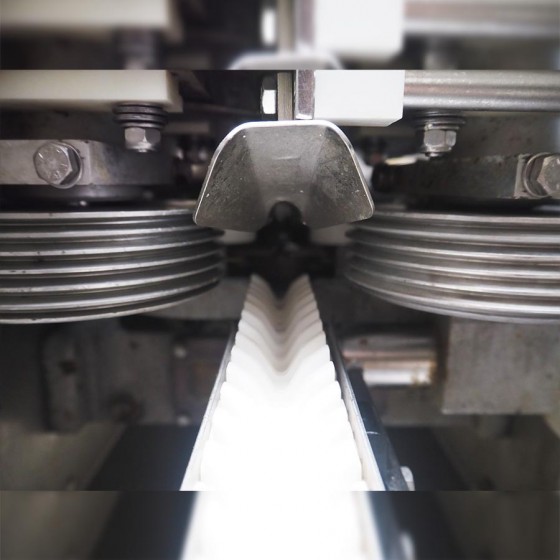

2. Baader 235 Filleting Machine

- Function: Precisely fillets fish to ensure high quality and minimal waste.

- Machine Number: 10037/100115

- Year of Manufacture: 1997

- Electrical Specifications: 400 V, 3 Ph, 50 Hz, 13.0 A

- Dimensions: 3400 mm x 1200 mm x 1700 mm

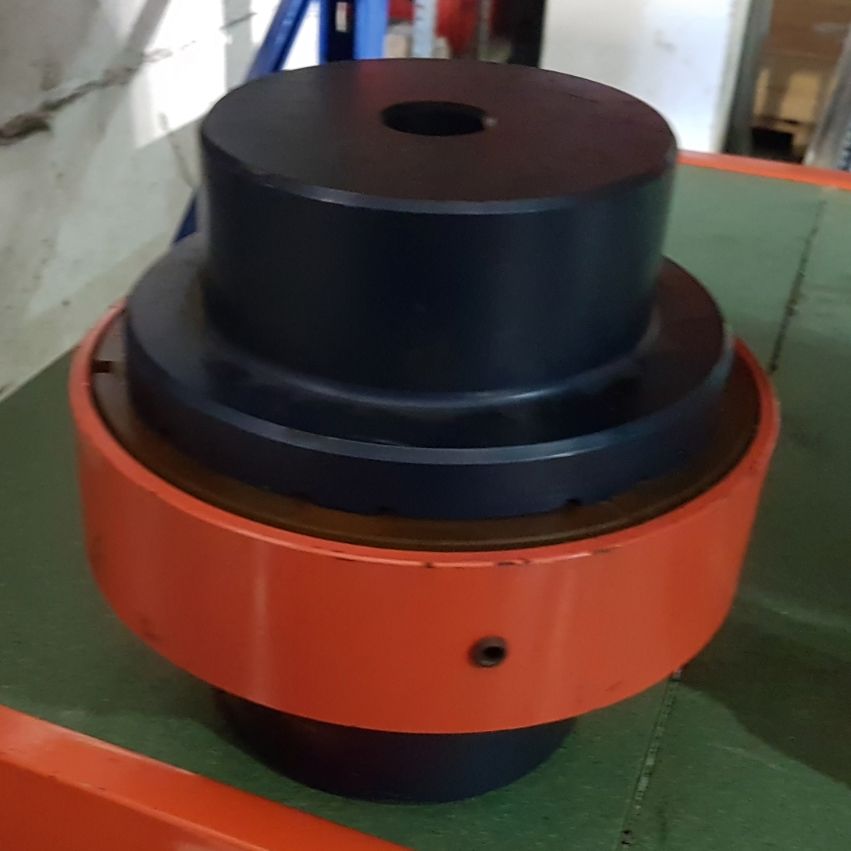

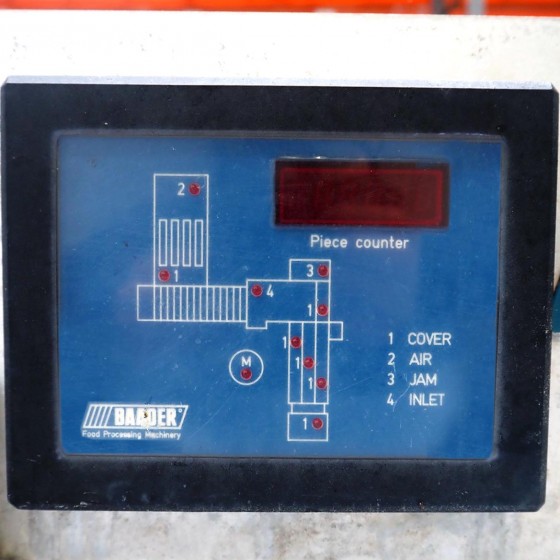

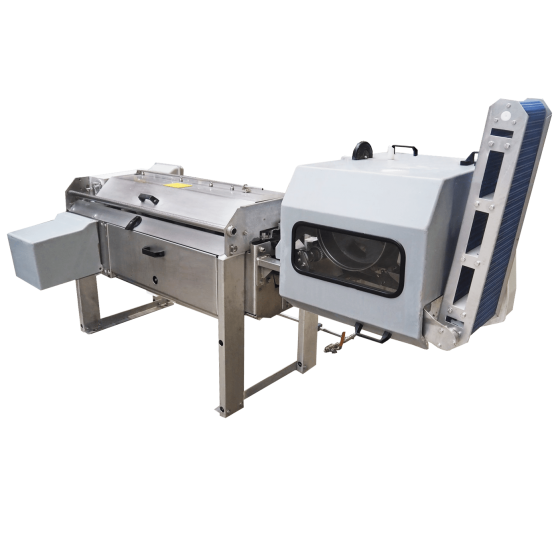

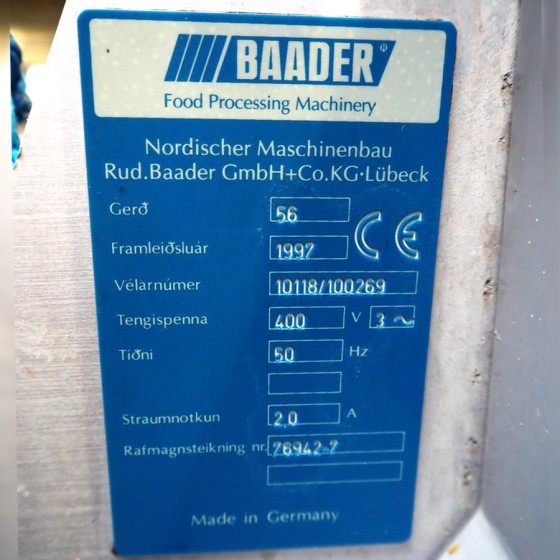

3. Baader 56 Skinning Machine

- Function: Precisely removes skin from fish fillets to deliver a clean product.

- Machine Number: 10118/100269

- Year of Manufacture: 1997

- Electrical Specifications: 400 V, 3 Ph, 50 Hz, 2 A

- Outfeed Belt: Plastic, 250 mm wide

- Dimensions: 3000 mm x 1200 mm x 1450 mm

With this Baader processing line, fish industry businesses can optimize their workflows, ensure product quality, and reduce production time. Each component is designed to meet the industry's demands, offering long-term reliability and performance.

For more information or inquiries about this product, please contact us directly.