Maja SR 500 A

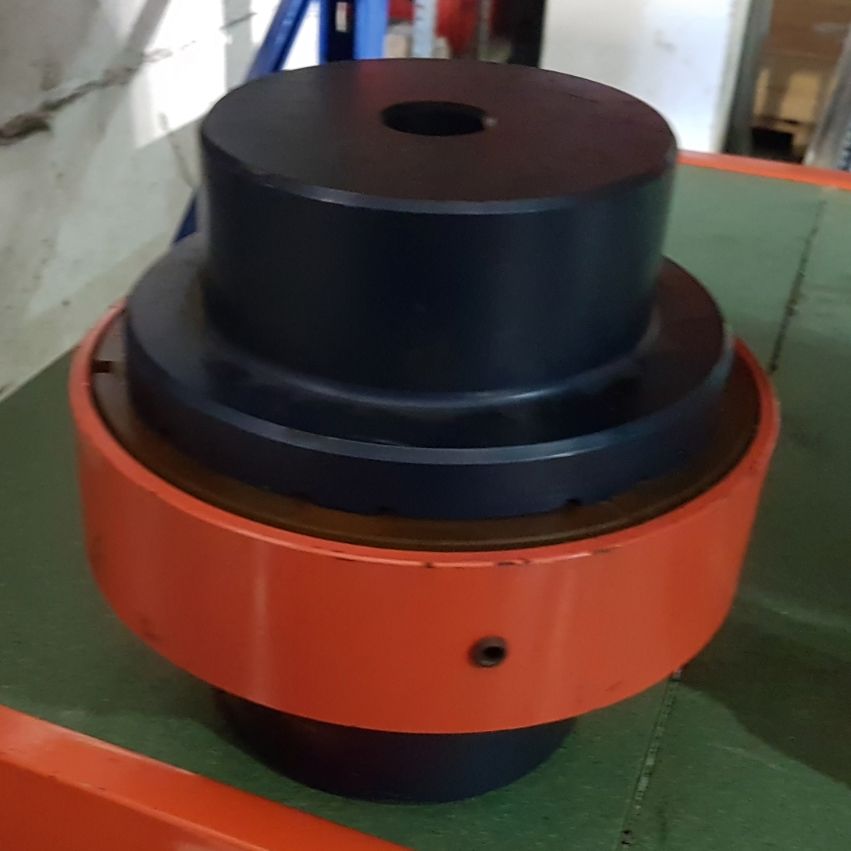

The Maja SR 500 A is a fully automatic mobile de-skinning and de-hiding machine, designed to optimize the membrane removal process on round cuts of pork, veal, and beef.

Manufactured in 2011, this machine features a robust construction and technical specifications that guarantee optimal performance in industrial operations.

Technical Specifications

- Type: SR 500 A

- Serial Number: M-49881

- Year of Manufacture: 2011

- Voltage: 400 V, 3-phase, 50 Hz

- Current Consumption: 4.8 A

- Power: 2 kW

Lifting Conveyor Belt

- Belt Type: Plastic with dividers

- Belt Width: 485 mm

- Divider Height: 30 mm

- Distance Between Dividers: 290 mm

- Lifting Height: 1400 mm

Discharge Belt

- Belt Type: Plastic

- Belt Width: 435 mm

- Overall Dimensions: 3300 mm x 1230 mm x 1700 mm

Key Features

- Full Automation: The SR 500 A automatically transports products using a system of synchronized conveyor belts, rotating the cuts to remove membranes from all sides. The duration of the de-hiding process can be individually programmed based on the material's consistency.

- Maximized Performance: Thanks to the individual adjustment of the de-hiding level, maximum performance is achieved independent of the operator's skill. Even untrained personnel can operate the machine without compromising de-hiding quality or performance.

- De-hiding Cycle Adjustment: The optimal de-hiding duration can be set for each product group via the control unit.

- Reduced Labor Requirements: Automation allows for significantly higher performance compared to manual de-hiding, eliminating the need for skilled personnel.

- Integration into Processing Lines: The SR 500 A can be integrated into existing processing lines, offering flexibility in line configuration.

- Enhanced Product Hygiene: Full automation minimizes product handling by staff, positively impacting product hygiene and shelf life.

Additional Equipment and Features

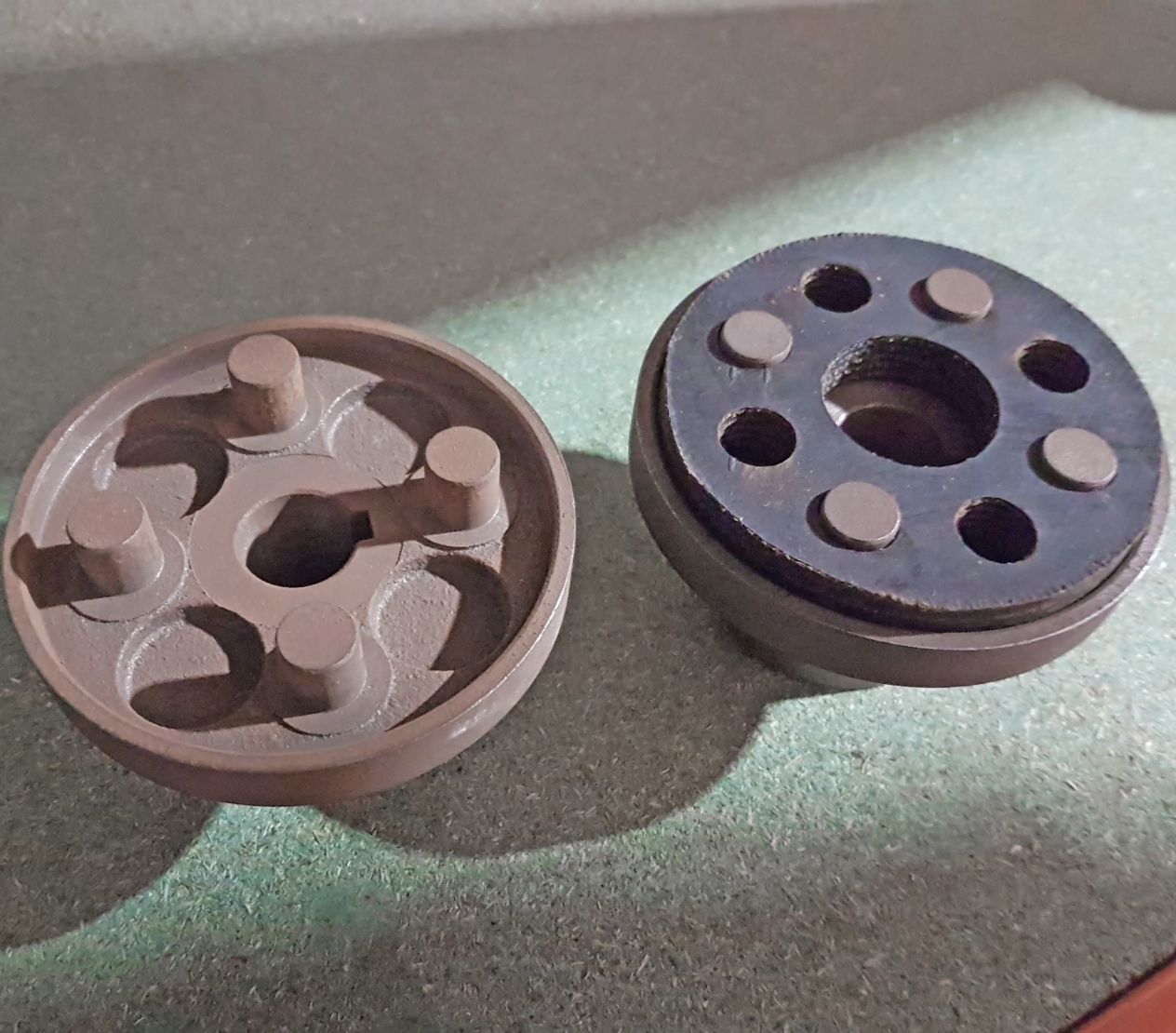

- Toothed Roller Cleaning with Compressed Air: For consistently perfect de-hiding results, the toothed roller is continuously cleaned of residual membranes using compressed air.

- Reduced Setup Times: Thanks to tool-free assembly and disassembly of machine parts.

- Quick and Easy Blade Change and Adjustment: Tool-free operation using a quick-release mechanism, allowing blade changes without the need for maintenance personnel.

- Easy and Safe Blade Support Handling: The blade support does not need to be removed for cleaning and blade replacement, reducing maintenance costs and increasing operational safety.

For more information about the Maja SR 500 A or to learn how it can be integrated into your production processes, please do not hesitate to contact us.